National Security

UConn is helping to secure the future, economically and strategically, by advancing the ways that we protect ourselves physically, digitally, and beyond.

The backbone of Connecticut’s skilled workforce comprises over 130,000 jobs in the aerospace and defense industries. UConn’s partnership programs with industry leaders like Pratt & Whitney, Sikorsky, and Electric Boat are advancing innovation across critical sectors. Through collaborations like the National Institute for Undersea Vehicle Technology (NIUVT), the UConn Shipbuilding Initiative, and the Air Force Advanced Manufacturing Initiative, the University’s research and workforce development efforts are aligned with evolving national security and maritime demands.

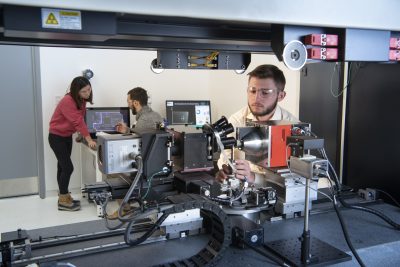

Researchers at the Pratt & Whitney Institute for Advanced Systems Engineering (PW-IASE) are making advances in field applications such as smart buildings and cities, aerospace systems, manufacturing and energy industries, robotics, and cybersecurity. Meanwhile, the Institute of Materials Science is meeting the demand for stronger, cheaper, lighter, more functional, and more sustainable materials for the latest in security hardware.

At UConn, security and innovation pave the way for the future.

Air Force Advanced Manufacturing Initiative

Provides transformative capabilities on manufacturing technologies to defense industry partners and supply chain to reduce scrap rates and increase yield/performance.

Collins Aerospace Center for Advanced Materials

Provides research opportunities in partnership with an industry leader in the aerospace and defense industries.

Connecticut Advanced Computing Center (CACC)

Investigates, develops, and promotes the best hardware- and software-based security practices in commercial and defense sectors.

National Institute for Undersea Vehicle Technology (NIUVT)

A collaborative partnership among government, academia, and industry, dedicated to conducting research, developing the workforce, and advancing technology in the undersea domain.

Pratt & Whitney Additive Manufacturing Center (PW AMC)

Utilizes a unique suite of thermophysical property measurement instruments to research fundamental aspects of additive manufacturing.

Pratt & Whitney Institute for Advanced Systems Engineering (PW-IASE)

Advances the science base of cyber-physical systems to accelerate their technological translation into sustained industrial growth.

Reverse Engineering Fabrication Inspection & Non-Destructive Evaluation (REFINE)

Uses state-of-the-art equipment to research failure analysis, forensic analysis, hardware security, hardware hacking, and reverse engineering of electrical components.

UConn Shipbuilding Initiative

Advancing shipbuilding and maritime capabilities through research, industry partnerships, and workforce development supporting regional and national maritime and defense needs.

UConn-Thermo Fisher Scientific Center for Advanced Microscopy and Materials Analysis (CAMMA)

Uses Thermo Fisher Scientific instrumentation, including nine state-of-the-art electron microscopes, to analyze various materials.