Advanced Manufacturing

UConn is a leader in advanced manufacturing, driving innovation through strong industry partnerships and cutting-edge facilities. As the manufacturing sector evolves with the Industry 4.0 revolution, UConn’s research and development are making significant impacts across the globe. By bridging academia, government, and industry, the University is shaping the future of manufacturing.

As a leader in manufacturing technology research, UConn works with major industry partners such as Pratt & Whitney, General Electric, and Lockheed Martin to align its research with today’s manufacturing needs. UConn's state-of-the-art facilities are leading to groundbreaking advances in additive manufacturing, advanced digital design, cyber-physical systems, energy efficiency, and precision engineering.

Center for Excellence in Sensor Technology and Diagnosis

Bridges academia and industry to drive innovation in critical sensor technology.

Connecticut Center for Applied Separations Technologies (CCAST)

Uses tech-agnostic research and development to identify energy- and cost-efficient solutions for the separations industry.

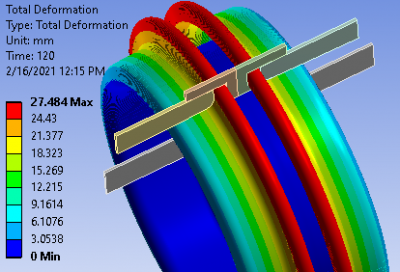

CT Manufacturing Simulation Center (CMSC)

Provides technical assistance to the Connecticut manufacturing community using high-performance computing-based modeling and simulation.

Digital Design, Research, Analysis and Manufacturing Center (D²REAM)

Enables the development of groundbreaking modeling and simulation capabilities to support advanced structural digital design and manufacturing.

Pratt & Whitney Additive Manufacturing Center (PW AMC)

Utilizes a unique suite of sophisticated thermophysical property measurement instruments and advanced 3D printers to research fundamental aspects of additive manufacturing.

Pratt & Whitney Institute for Advanced Systems Engineering (PW-IASE)

Advances the science base of cyber-physical systems to accelerate its technological translation into sustained industrial growth.